Window/Door

This handout is a compilation of some of the standard requirements based on the State Building Code and City Ordinance for projects of this type. This information packet does not contain all the specific codes for construction and should only be used as a guide. The permittee is responsible to meet all code requirements applicable to each project.

Note: If home is a Heritage Preservation Site prior approval from city planner and/or HPC is required before issuance of permit.

Submittals

- Permit application-Siding/Roofing/Window

- Number of windows/doors to be replaced.

- If changing window or door opening size, or placing a new window or door, we will require a separate building permit application and construction plans that detail:

- Window/door location

- Elevation view of existing structure

- Header and stud details

Required Inspections

- Photos showing every prepared opening prior to window/door installation. All photos must be clear, in color, and taken in a way where it is easy to distinguish one window/door from another (ex. include room fixtures, distinct walls, etc.)

- Photos of window flashed after installation if applicable.

- Final: schedule after photos have been submitted. Interior & exterior access is required to inspect new windows/doors and Smoke & CO alarms throughout the home.

Flashing of Windows and Doors

R703.4 Flashing. Approved corrosion resistant flashing shall be applied shingle-fashion in such a manner as to prevent entry of water into the wall cavity or penetrations of water to the building structural framing components. The flashing shall extend to the surface of the exterior wall finish. Approved corrosion resistant flashings shall be installed in the following locations:

1. Exterior window and door openings. Flashing shall be installed at the head and sides of exterior window and door openings and shall extend to the surface of the exterior wall finish or to the water resistive barrier for subsequent drainage. Flashing at exterior window and door openings shall be installed in accordance with at least one of the following:

a. The manufacturer’s installation and flashing instructions.

b. In accordance with the flashing design or method of a registered design professional

c. In accordance with other approved methods.

R703.4.1 Pan flashing of windows and doors.

Pan flashing shall be installed in accordance with the fenestration manufacturer’s installation and flashing instructions. Where flashing instructions or details are not provided, pan flashing shall be installed at the sill of exterior window and door openings. Pan flashing shall be sealed or sloped in such a manner as to direct water to the surface of the exterior wall finish or to the water-resistive barrier for subsequent drainage.

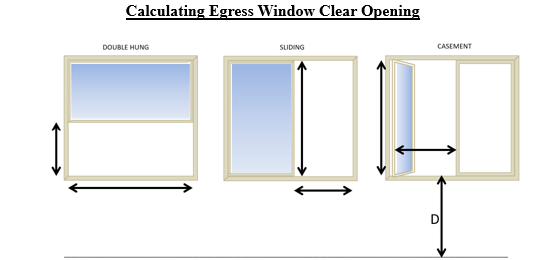

| Enter Clear Opening Width (Must be a minimum 20-inches) | |

| Enter Clear Opening Height (Must be a minimum of 24-inches) | X |

| Width x Height = Clear Opening | = |

| Dimension 'D' must be 44" or less (finished floor to clear opening) |

R310.1.1 All emergency escape and rescue openings shall have a minimum net clear opening of 5.7 square feet (820 square inches)

Exception: Grade floor openings shall have a net clear opening of 5 square feet (720 square inches)

Grade Floor Opening: An opening located such that the sill of the opening is not more than 44” above or below the finished ground level adjacent to the opening.

R310.1 Emergency escape and rescue opening required.

Basements, habitable attics, and every sleeping room shall have not less than one operable emergency escape and rescue opening. Additional information can be found on MN DLI Emergency Escapes Handout.

R310.2.5 Replacement windows.

Replacement windows installed in buildings meeting the scope of this code shall be exempt from the maximum sill height requirements of Section R310.2.2 and the requirements of Section R310.2.1, provided that the replacement window meets the following conditions:

1.The replacement window is the manufacturer's largest standard size window that will fit within the existing frame or existing rough opening. The replacement window is of the same operating style as the existing window or a style that provides for an equal or greater window opening area than the existing window.

2. The replacement window is not part of a change of occupancy.

Safety Glazing in Hazardous Conditions

R308.4.2 Glazing adjacent to doors

Glazing in an individual fixed or operable panel adjacent to a door shall be considered to be a hazardous location where the bottom exposed edge of the glazing is less than 60 inches (1524 mm) above the floor or walking surface and it meets either of the following conditions:

1. Where the glazing is within 24 inches (610 mm) of either side of the door in the plane of the door in a closed position.

2. Where the glazing is on a wall less than 180 degrees (3.14 rad) from the plane of the door in a closed position and within 24 inches (610 mm) of the hinge side of an in-swinging door.

Exceptions:

1. Decorative glazing.

2. Where there is an intervening wall or other permanent barrier between the door and the glazing.

3. Where access through the door is to a closet or storage area 3 feet (914 mm) or less in depth. Glazing in this application shall comply with Section R308.4.3.

4. Glazing that is adjacent to the fixed panel of patio doors.

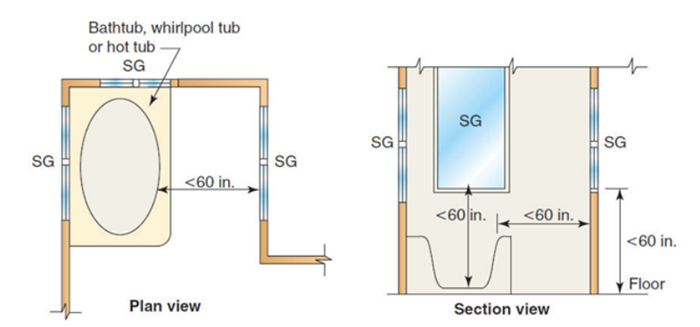

R308.4.5 Glazing and wet surfaces. Glazing in walls, enclosures or fences containing or facing hot tubs, spas, whirlpools, saunas, steam rooms, bathtubs, showers and indoor or outdoor swimming pools where the bottom exposed edge of the glazing is less than 60 inches (1524 mm) measured vertically above any standing or walking surface shall be considered a hazardous location. This shall apply to single glazing, and all panes in multiple glazing.

Exception: Glazing that is more than 60 inches (1524mm), measured horizontally and in a straight line, from the water’s edge of a bathtub, hot tub, spa, whirlpool, or swimming pool or from the edge of a shower, sauna, or steam room.

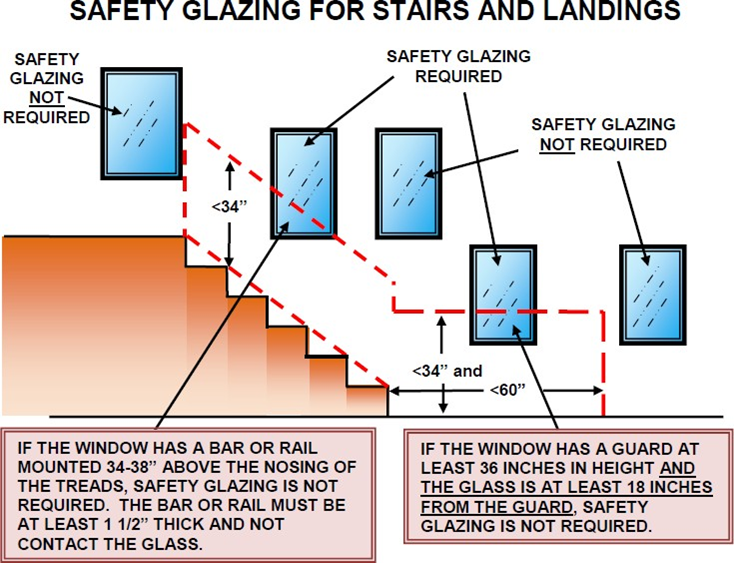

R308.4.6 Glazing adjacent to stairs and ramps.

Glazing where the bottom exposed edge of the glazing is less than 36 inches (914 mm) above the plane of the adjacent walking surface of stairways, landings between flights of stairs and ramps shall be considered to be a hazardous location.

Exceptions:

- Where glazing is adjacent to a walking surface and a horizontal rail is installed at 34 to 38 inches (864 to 965 mm) above the walking surface. The rail shall be capable of withstanding a horizontal load of 50 pounds per linear foot (730 N/m) without contacting the glass and have a cross-sectional height of not less than 11/2 inches (38 mm).

- Glazing 36 inches (914 mm) or more measured horizontally from the walking surface.

R308.4.7 Glazing adjacent to the bottom stair landing.

Glazing adjacent to the landing at the bottom of a stairway where the glazing is less than 36 inches (914 mm) above the landing and within a 60-inch (1524 mm) horizontal arc less than 180 degrees (3.14 rad) from the bottom tread nosing shall be considered to be a hazardous location.

Exception: Where the glazing is protected by a guard complying with Section R312 and the plane of the glass is more than 18 inches (457 mm) from the guard.

Building Safety

Phone: 651-480-2342

Sign up to our News and Notices

Stay up to date on the city's activities, events, programs and operations by subscribing to our news, notices and publications.