Garage & Accessory Structure

This handout is a compilation of some of the standard requirements based on the State Building Code and City Ordinance for projects of this type. This information packet does not contain all the specific codes for construction and should only be used as a guide. The permittee is responsible to meet all code requirements applicable to each project.

Submittals

- Permit application-Building

- Site plan/survey showing the location of the proposed structure, distance to property lines and other structures (house, accessory structures)

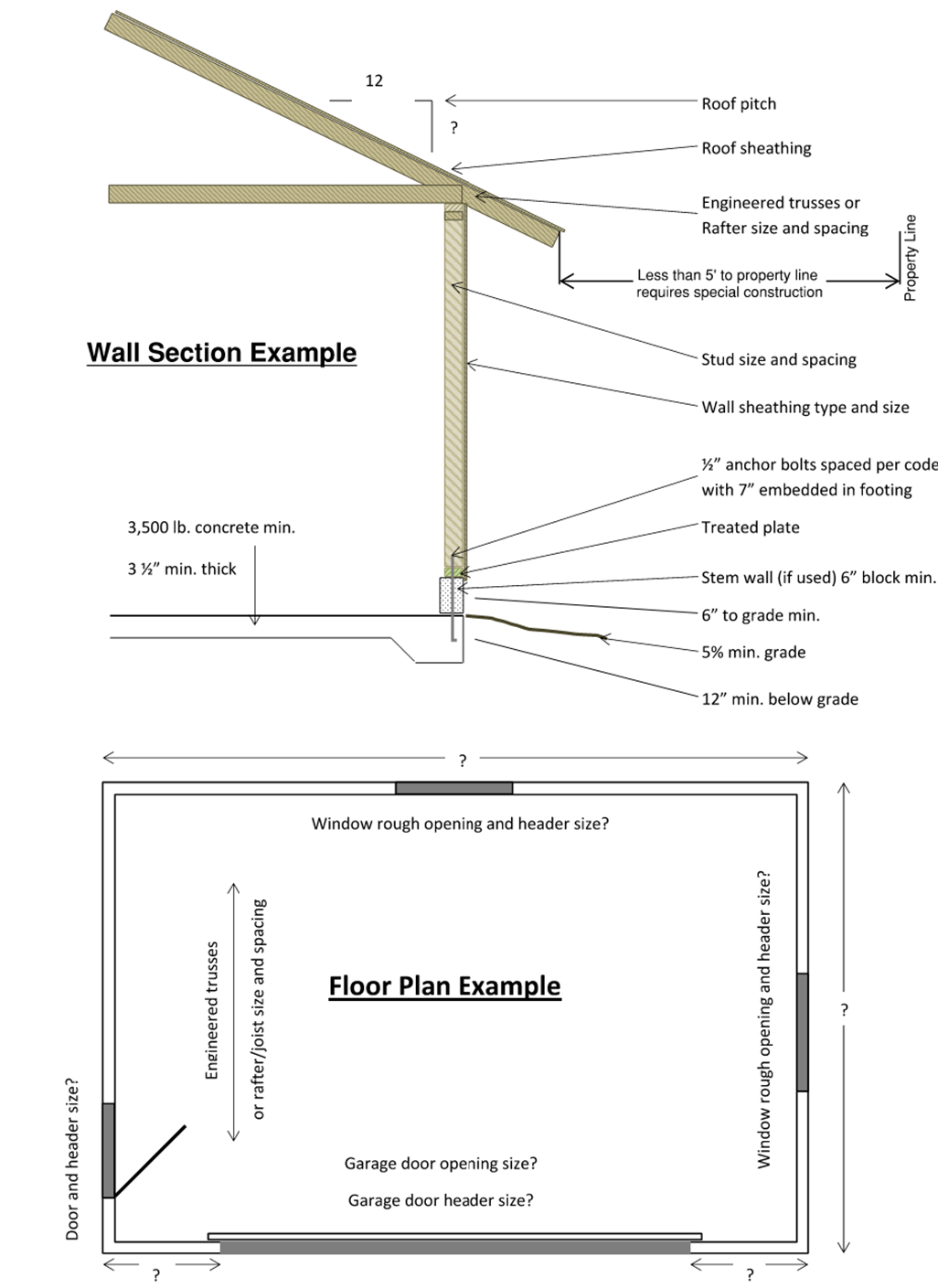

- Construction plans including foundation, wall bracing, truss and header specs

- Accessory structure worksheet

- Mechanical permit application (if applicable)

- Plumbing permit application (if applicable)

- Electrical permit application (if applicable)

- Owner-contractor waiver if homeowner is completing the work themselves

Required inspections

Complete permit package and plan set must be on site

- Footing (before concrete is poured)

- Foundation

- Sheathing (before WRB installation)

- Framing (stamped truss drawings required)

- Water resistive barrier (photos acceptable)

- Ice and water (if applicable, photos acceptable)

- Final

Typical Code Requirements for Garages and Accessory Structures

- Zoning: Review Residential Accessory Structure Zoning Handout for specific zoning requirements.

- Call 811: prior to digging contact Gopher State One Call to verify utility locations. 48-hour notice is required.

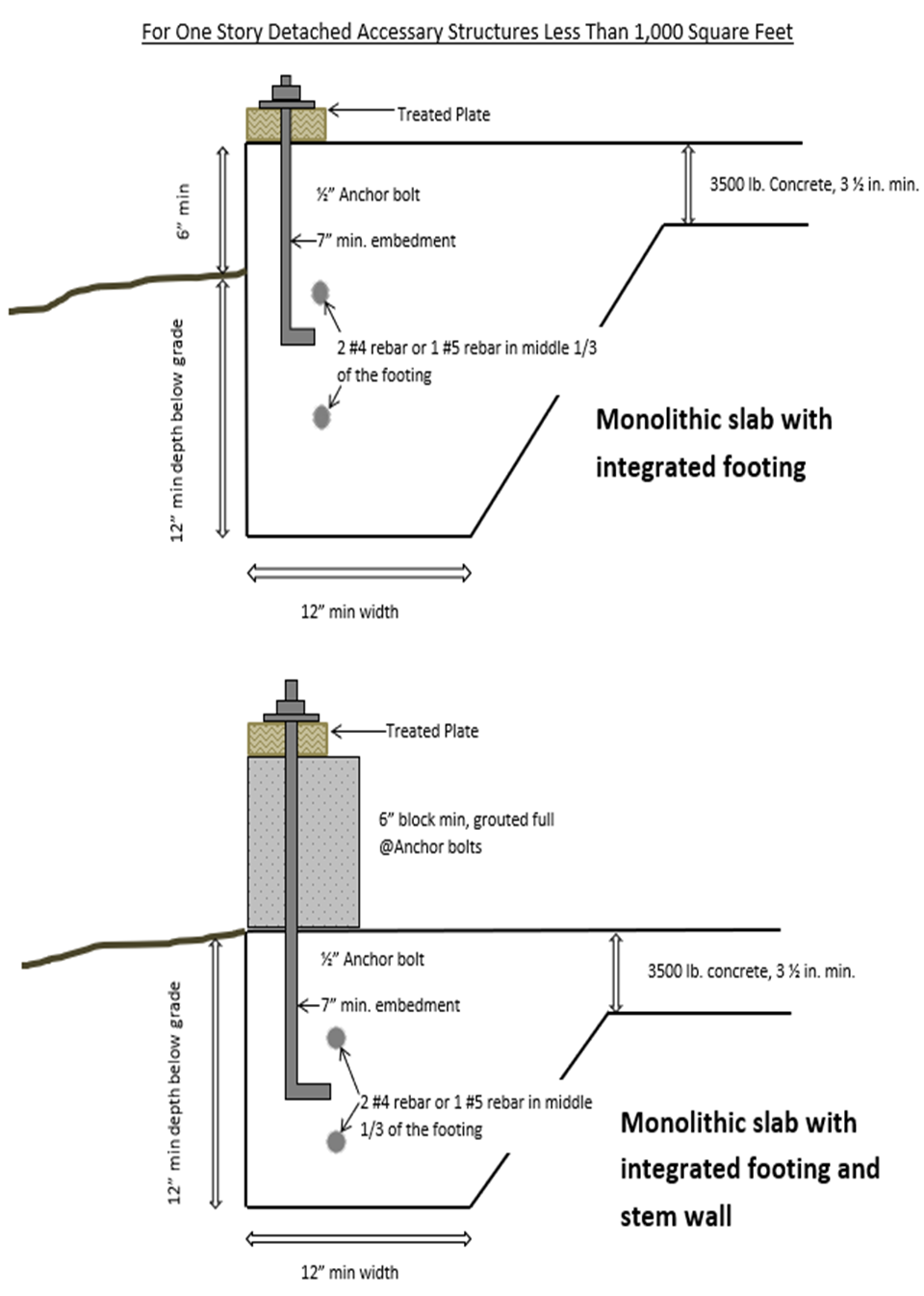

- Footings: Footings must extend to frost depth for all structures attached to the house. A monolithic slab with integrated footing may be used for one story detached structures less than 1000 square feet on all soils except peat and muck. (See attached for monolithic slab example.)

- Anchor bolts: Sill (sole) plates must be anchored to the foundation with not less than ½” diameter steel bolts or approved straps embedded at least 7” into the concrete. Anchors bolts shall not be spaced more than 6’ apart with a minimum of 2 anchor bolts per section of plate and an anchor bolt placed not more than 12” from the end of each individual plate. They must be located within the center 1/3 of the sole plate. Anchor straps must be installed according to manufacturer’s specifications. Anchor bolts must be available at footing inspection.

- Sill (sole) plate: Sill plates shall be of naturally durable wood or wood that is preservative treated in accordance with AWPA U1 for the species, product, preservative, and end use.

- Wall framing: Studs must be placed with their wide dimension perpendicular to the wall. The minimum stud size is 2”x 4” and not more than 24” on center.

- Top plate: Stud walls shall be capped with a double top plate installed to provide overlapping at corners and intersections with bearing partitions. End joints in top plates shall offset at least 24”. Plates shall be not less than 2” nominal thickness and have a width at least equal to the stud width.

- Sheathing: Approved wall and roof sheathing must be installed according to manufacturer’s specifications and approved wall bracing plan.

- WRB: A weather resistive barrier is required prior to installation of siding. Photos are acceptable. Must have required flashing installed at time of inspection/photos.

- Attached garages: Not less than ½” gypsum board must be applied to the garage side from floor plate to roof sheathing.

- Wood ground separation: Untreated wood sheathing and siding must maintain 6” minimum clearance to the ground.

- Stem wall (curb block): Concrete masonry blocks used for stem wall (curb block) must be a minimum 6” modular width.

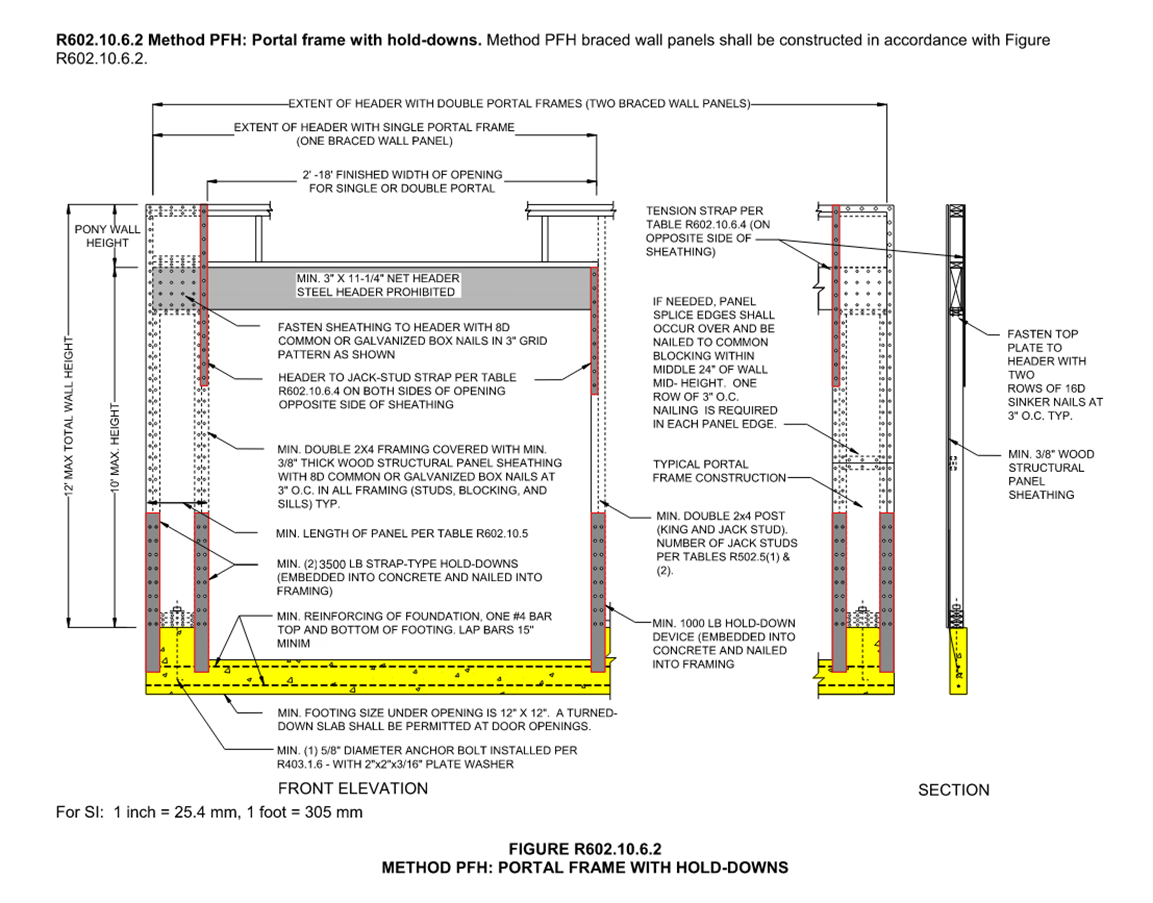

- Narrow wall panel: Special construction with enhanced anchorage may be required where walls adjacent to openings are less than 48”. See PFH-portal frame with hold-downs detail. Other portal frame options may include PFG- Portal Frame at Garage, CS-PF- Continuously Sheathed Portal Frame.

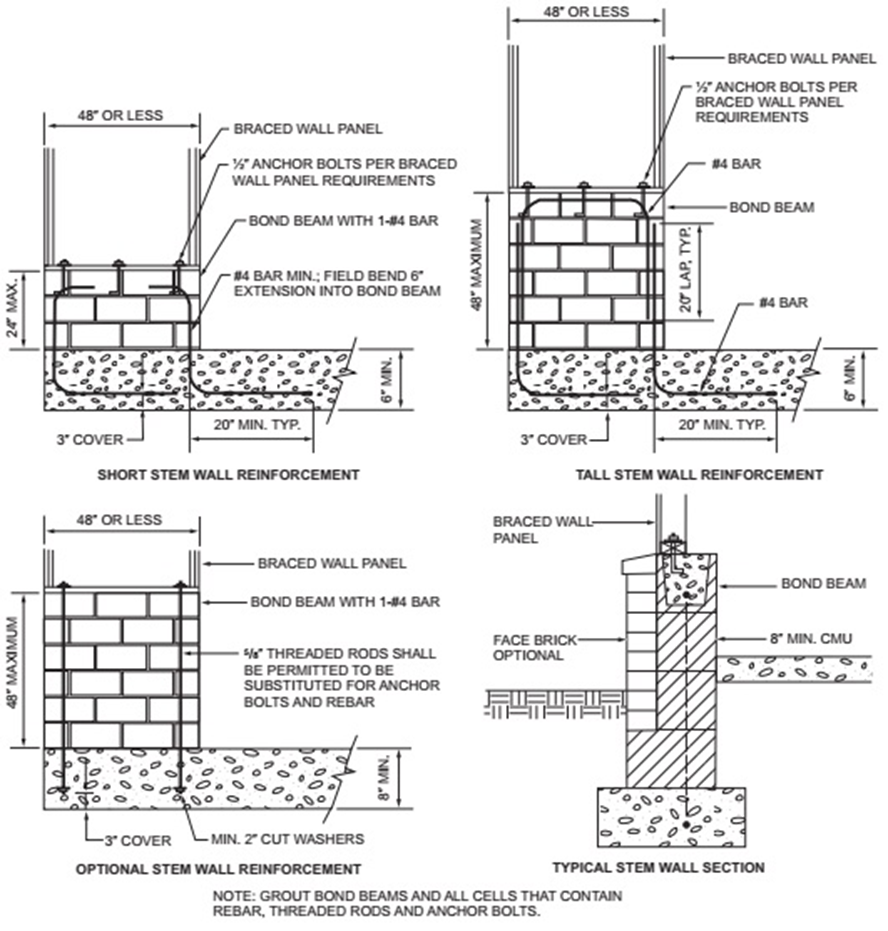

- Stem wall reinforcing: Masonry stem wall with a length of 48” or less supporting braced wall panels shall be reinforced in accordance with Figure 602.10.9.

- Attic ventilation: Buildings with finished ceilings require attic ventilation. It must be supplied evenly distributed total opening area may be 1/300th of the attic area.

- Automatic garage door openers: must have a safety device that causes a closing door to open and prevents an open door from closing when a person or obstruction is encountered in the door’s path. The device must be labeled UL325.

FIGURE R602.10.9 MASONRY STEM WALLS SUPPORTING BRACED WALL PANELS

R602.10.9 Braced wall panel support.

Masonry stem walls with a length of 48 inches (1219 mm) or less supporting braced wall panels shall be reinforced in accordance with Figure R602.10.9. Masonry stem walls with a length greater than 48 inches (1219 mm) supporting braced wall panels shall be constructed in accordance with Section R403.1 Methods ABW and PFH shall not be permitted to attach to masonry stem walls.

Building Safety

Phone: 651-480-2342

Sign up to our News and Notices

Stay up to date on the city's activities, events, programs and operations by subscribing to our news, notices and publications.